Our Technology

Hypercharge Technology’s focus is predominantly within the chemistry and system engineering process. We take a universal approach to our design and research to ensure compatibility across our battery design range.

Our Approach

Universal approach to fast charging

Anode

Coated layered nanoparticles, embedded in organic conductive matrix

Cathode

Proprietary compounds for enhanced stability and safety

Electrolyte

High voltage capability, enhanced safety with dendrite prevention

Data Science

Artificial Intelligence and Machine Learning, automated optimization of material compounds

Cell Structure

Thin layer coating, optimized for ultra-fast charging thermal management

Electronics

Dynamic charging profiles with real time voltage management

97 granted and

55 pending patents

Why Flash Battery technology is the future?

Extreme-fast charging

Battery is fully charged in minutes

Innovative formulation optimized for

Cycle life Energy density Safety

Materials

Proprietary organic compounds combined with nano-materials, based on strong artificial intelligence and machine learning

Production

Scalable production, utilizing existing manufacturing facilities with minor modifications

Technology highlights

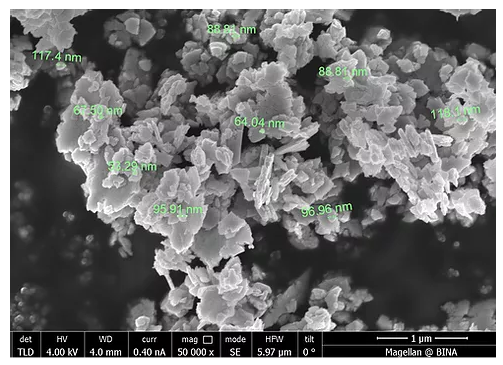

- Nano Materials: High electrochemical energy nano-particles as active material is important for high electrochemical activity and are designed to increase conductivity. nano-particles enable ultra-fast charging and higher storage density.

- Organic Binders: Proprietary anode binder used to adhere particles of active materials and conductive additives; optimized to have low impedance to current flow.

- Organic Electrode Additives: Proprietary organic compound additives in the electrodes reduce mechanical strain and prevent undesired side reactions between the electrode and electrolyte.

- Organic Electrolyte Additives: Tailored electrolyte additives provide metalloid anodes increased surface and bulk stabilities, improving long-term cycling and calendar life.

- Formation process: enables stable solid electrolyte interphase (SEI) for preventing irreversible consumption of electrolyte and lithium ions.

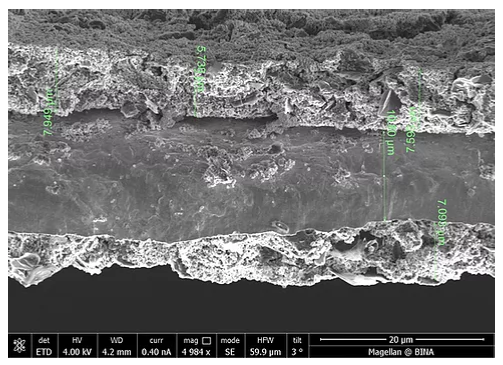

Using nano-materials and organic compounds

coated in a very thin layer of up to 10 microns

Particle size

Nano size active materials that enable ultra fast Li ion diffusion

Anode cross section

Thin layer electrodes which consist of high electrical conductivity matrix with high capacity

Addressing Si Challenges

Cell design should include

- High current

- HLow resistance

- HUnique formation

The cell should avoid

- Dendrite formation

- Swelling of the active materials

At the system level

- Cells assembled in the pack must be balanced and have low resistance

- Extreme-fast charging should work well under low temperatures

Extreme-fast charging battery design